Thermal paste (also called thermal silicone or thermal putty) is a substance that improves the conduction of heat between the surfaces of two or more objects that may be irregular or not be in direct contact. Thermal paste is used to join (paste, in a way) the processor with the base of the heat sink, improving the passage of heat from the processor to the heat sink to dissipate the heat generated by the CPU. Application of thermal paste isn’t at all difficult, but we have to be careful; if we use too much, we might achieve the opposite of the desired effect and end up raising the CPU’s temperature. So be patient and be careful.

Definitions

Before beginning, let’s clarify a few terms to ensure that we apply the thermal paste in a determined manner.

- IHS: Integrated heat spreader. A small metallic sheet that covers the processor, this mainly protects the

- DIE: The most internal part of a processor. Basically, it’s the processor in and of itself where you’ll find all the cores, memory, cache, etc.

- PCB: The base plate of any component. For example, the base plate that holds all the components of the graphics card. May be green, blue, black, and so on.

What is thermal paste, really? And why is it necessary?

The IHS of current processors isn’t 100% smooth and without malformations, and neither is the base of heat sinks; thus, if the IHS and the base of the heat sink aren’t in complete contact, heat can’t get to the heat sink and the temperature of the processor will increase. For this reason we need thermal paste, which better units the processor and the base of the heat sink, getting around any malformations or irregularities that either may have.

The efficiency of thermal paste is measured in watts per meter-Kelvin W/(m•K), which is the quantity of thermal energy dissipated in a certain amount of time. The higher the dissipation capacity, the better the thermal paste.

In ULITE we’ve published a guide with all the types of thermal paste and the best kinds to use according to price. Take a look at it here.

Applying thermal paste to Intel

It depends on the architecture of the Intel processor. From Sandy bridge onward (i5-2500K, i7-2600K), thermal paste is applied in a line because its DIE is retangular in shape and we want all of the DIE to have maximum conductivity with the heat sink in that zone.

In the image we can see the interior of an Intel Core i7 3770K processor (Ivy bridge, third generation). As we can see, the DIE is rectangular and is placed in a vertical manner on the PCB, so, as we explained above, the best way of applying thermal paste to Intel processors from Sandy bridge onward is in a vertical line and in a reasonable quantity that’s just right.

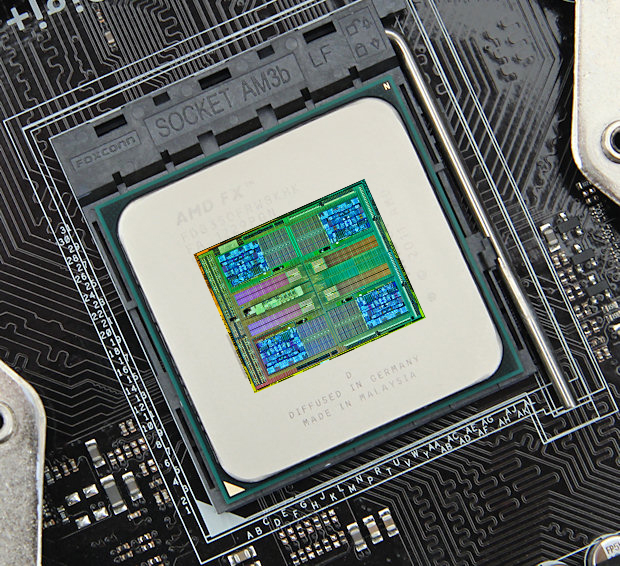

Applying thermal paste to AMD

With AMD it’s different. The DIE is in the form of a square (not exactly, but it’s more square-like than Intel’s DIE), so for AMD processors the thermal paste must be on the center of the processor, regardless of the type of architecture.

Since the DIE is square shaped, the best way to apply the paste on AMD processors is a little in the center so that the pressure of the heat sink can flatten and expand it. Apply just a little: a drop of thermal paste the size of a grain of rice or a little bigger.

As you all see, there’s not much science to the application of thermal paste. You only need to be careful and apply a reasonable amount. This is especially true for special kinds of thermal paste that may conduct electricity, or thermal pastes made of liquid metal.